Enquire Form

Home >> Taglus PU Flex

-

Taglus PU Flex

Smartest material properties and enhanced esthetics

Taglus® PU Flex is a homogeneous polyurethane sheet that consists of linear polymeric chains made of alternating flexible and rigid segments. It is a high-performance aligner and retainer material that provides excellent flexibility, strength, and durability, while also providing comfort for the wearer.

-

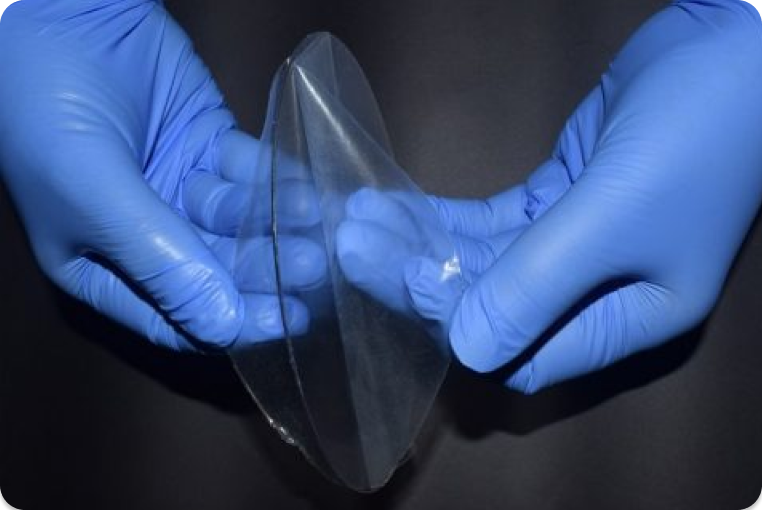

- Highly flexible :Unique formulation results in resulting in higher toughness yet more flexibility

- Comfortable and durable :High value of elongation at break reduces the risk of aligner cracks

- Brilliant wear and tear resistance : Designed for long term wear to withstand tooth forces

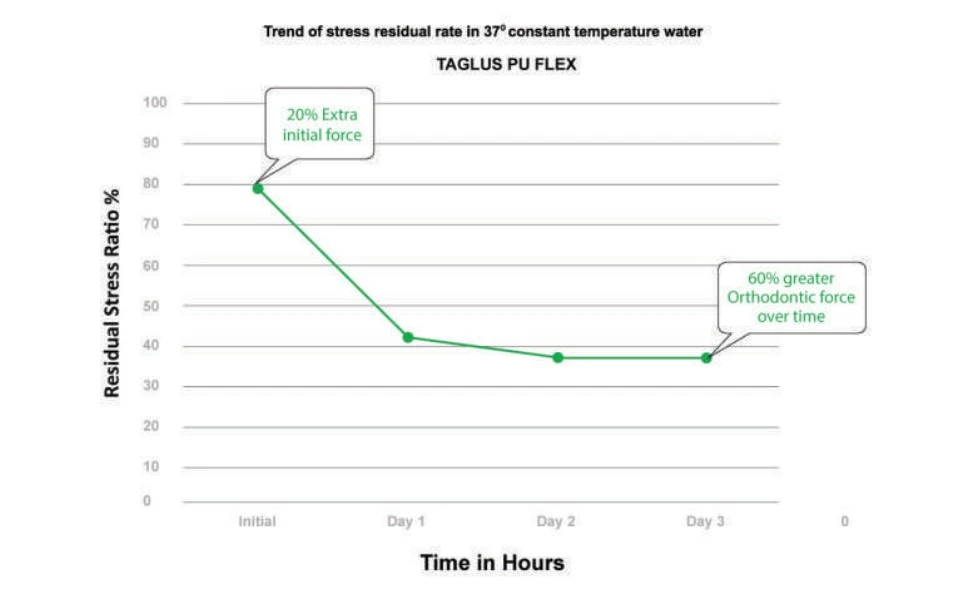

- Orthodontic forces :Generates 20% more initial forces Vs other PU materials

Properties

In applications where plastic films are designed to withstand orthodontic forces in an aligner, the mechanical properties of polymers namely Strength, Stiffness & Toughness play a vital role. Such properties of Taglus® PU Flex sheets when investigated using standardized test methods, e.g. tensile stress as per ASTM D 638: 2014 by briefly applying load in one direction the approximate results and values observed during such test, demonstrate that Taglus® PU Flex has the highest tensile stress at the break in its class approximately equal to 61 MPa. So, it is an optimal balance of rigidity with elasticity. The test was performed by a NABL accredited Laboratory complying with ISO/IEC 17025 Laboratory Management System.

Taglus® PU Flex sheets have a very high value of elongation at break. With an approximate value of 100%, the material can stretch up to 100 percent of its original dimensions before it breaks, this eliminates the worries of aligner cracking.

The water absorption data is important to understand the performance of the Taglus® PU Flex sheets during processing e.g. Thermoforming as well as in water or humid environments especially in saliva in the mouth, to avoid premature moisture-related failures. Taglus® PU Flex sheets when tested for 24 hours water absorption test exhibited only 0.15% weight changes against the industry-accepted chemical resistance standard of <3%.

Owing to the presence of alternating flexible and rigid segments, the polymer toughness is highly increased. When measured Un-notched Izod Impact Strength as per ASTM D256 @73°F (23°C) in 0.125” thickness, the value was approximately 85 J/m (No Break) indicating it is a virtually unbreakable aligner thermoforming foil.

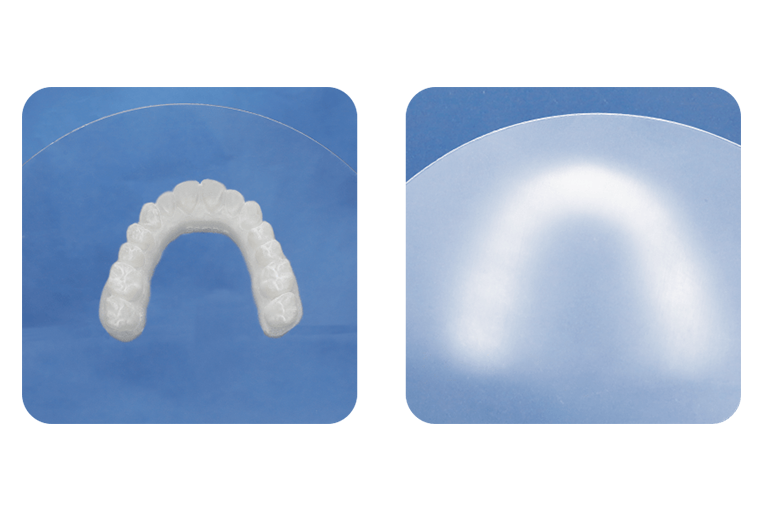

The photographs of Taglus® PU Flex sheets when compared with other PU-based aligner sheets show a noticeable diference in the clarity of the object placed at a distance from the sheet. Taglus® PU Flex sheets have the highest clarity in their class of other PU-based aligner thermoforming foils.

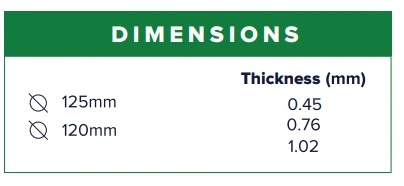

Sizes