Enquire Form

about us

Why Taglus

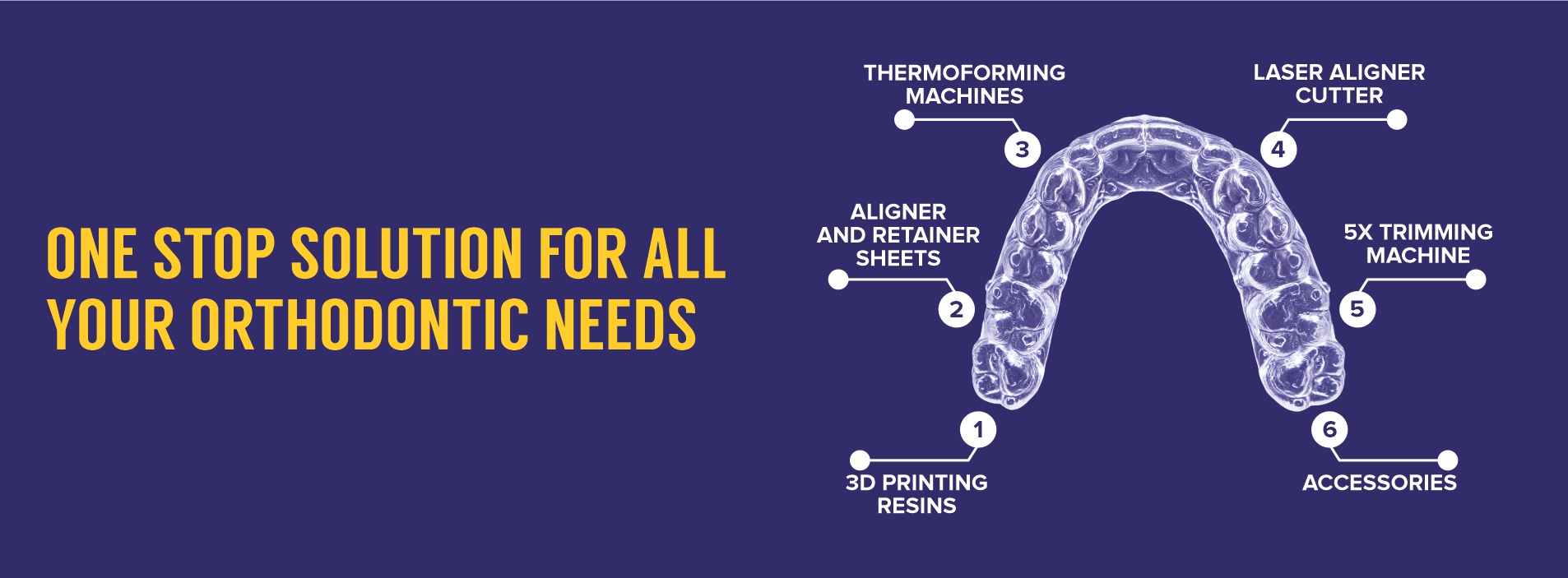

Taglus is a global industry leader in the manufacture of innovative dental aligner and post-treatment retainer thermoplastic sheets that are made using cutting-edge technology, and quality liquid resins for 3D printing. International quality assurance certifications of these materials confirm their high standards.

PRoducts

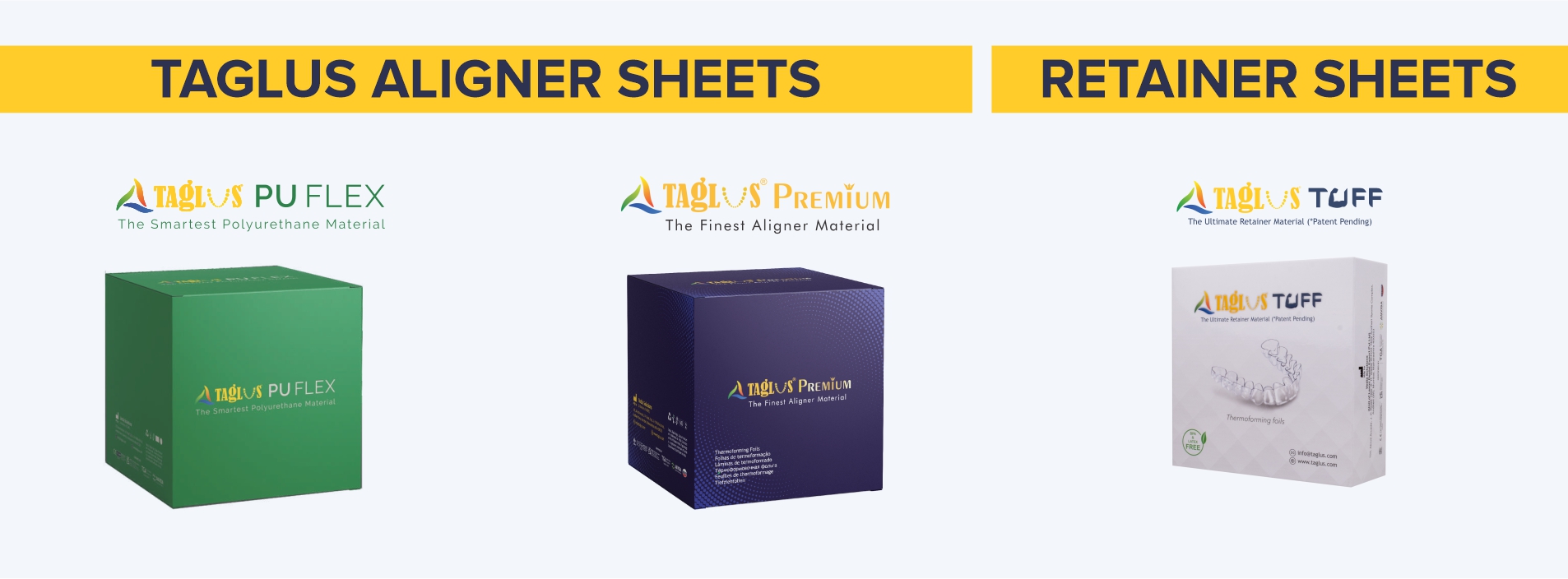

Aligner Sheets

Retainer Sheets

3d Printing Resins

testimonials

What Our Customer say

-

“I have been very happy after the trial of Taglus in my laboratory, so much so that it will now be offered to all our customers for retainers. All aligner cases will also be manufactured using Taglus aligner material. Overall, the new Taglus aligner/retainer material has my approval and will be definitely used in my laboratory.”

Mr. Joe Schiavello

Orthoshop, Australia

-

“In the past we were using other big brands and we saw a great difference on how clear was the final product, the easiness of use on all stages ,cutting polishing etc.Since we Taglus sheets on aligners and retainers we also saw great difference regarding other brands on the fact that it doesn’t color so fast and it's abilities on teeth movements is as described.”

Amalia Tsetsou

Dental Lab Technician

-

“Taglus is always very helpful ,fast responding and with a very fast delivery despite the great distance and the Covid-19 virus situation which is a factor affecting every business in the world.The quality of the products is excellent and this comes not only by our own lab and the results on patients using aligners and retainers made with Taglus sheets but also from customers feedback received by our sellers.”

Dr.Anastasios Drakos

-

“I have been using Taglus Premium for my aligners for over 3 years with excellent results. They have very good mechanical properties to achieve the intended results.”

Manuel Fernández Cano , Spain

-

“Using the proper staging technique, the right sheet material, thickness mild to moderate crowding cases could be treated efficiently using in-house aligners. Taglus Sheets done the job perfectly as wanted.”

Dr. Abdullah Ali, Egypt

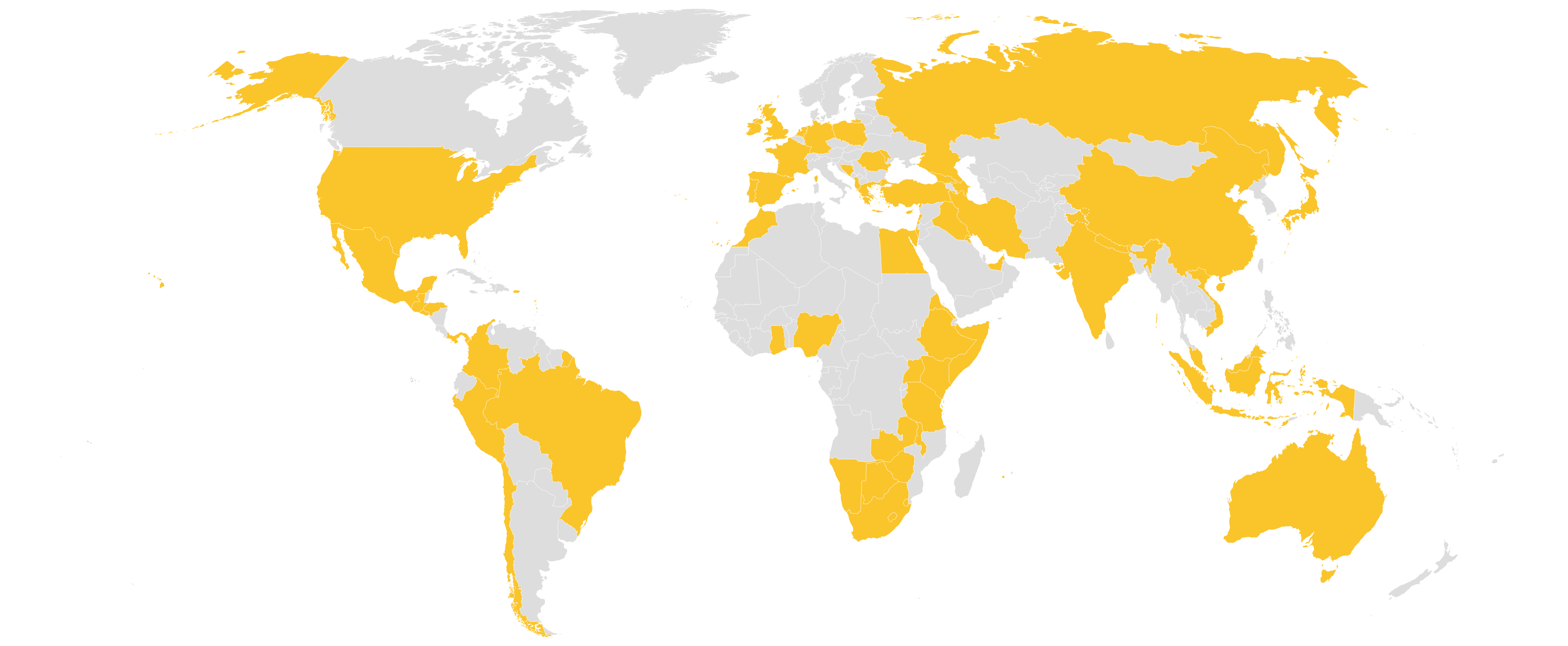

distributors

OUR DISTRIBUTION NETWORK

Know More About Us

SignUp To Our Newsletter And Get To Know More About Taglus

Copyrights@taglus-2026

*Taglus is a trademark of Vedia Solutions