Enquire Form

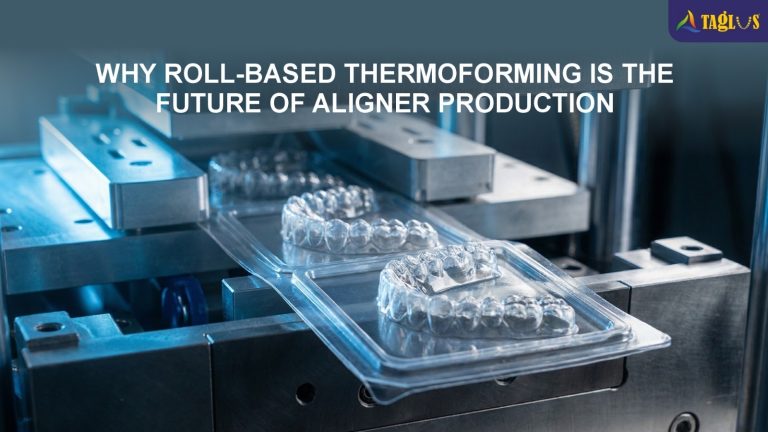

Why Roll-Based Thermoforming Is the Future of Aligner Production

Aligner demand is exploding, and case volumes have almost doubled in many labs. Production lines also must change the workflow because the solutions that may have appeared sufficient five years ago now prove to fall short in certain aspects.

Sheet-based thermoforming built the industry initially and provided enough support in the emerging industry. But with the skyrocketing demand and popularity, roll-based thermoforming will run parallel to increased industrial evolution.

Labs that plan for long-term growth already know this. The future of aligner production depends on automation, speed, and zero waste. Roll-based thermoforming delivers all three.

The Problem with Traditional Sheet Thermoforming is that it has limits , such as:

- High manual handling

- Slower cycle times

- More material waste

- Inconsistent heating zones

- Higher labor dependency

As volumes grow, these problems multiply because of a lack of time and high demand.

The financial profit also gets overshadowed because then you need more operators, more machines, more floor space and the error rate goes up, and simultaneously consistency goes down, and this kind of complex workflow is not sustainable at scale production.

What Is Roll-Based Thermoforming?

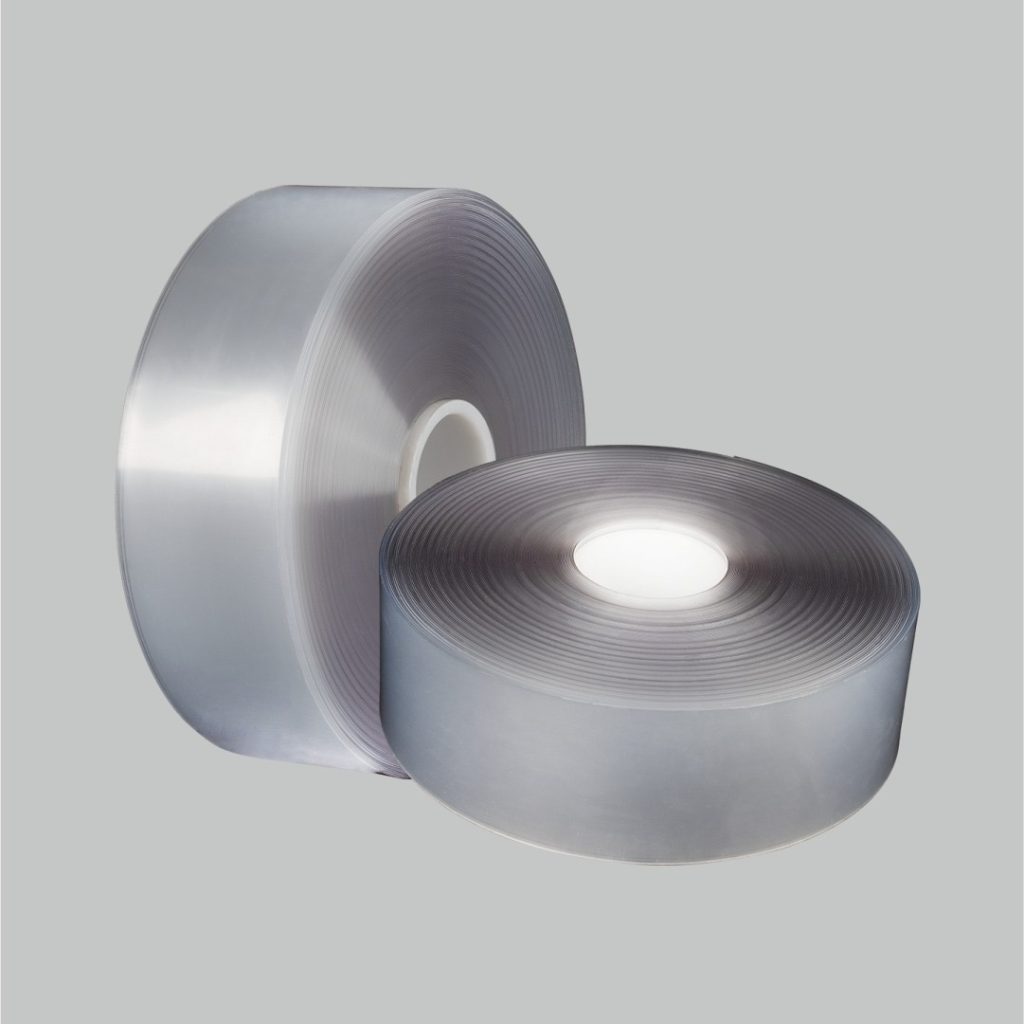

Instead of loading individual sheets, roll-based systems feed continuous aligner material directly into the thermoforming machine.

This system:

- Pulls material from a roll

- Heats it with uniform thermal control

- Forms aligners continuously

- Cuts automatically

- Maintains constant thickness

- It works like an industrial production line, not a dental lab workstation.

Why Roll-Based Systems Change Everything

1. Massive Production Speed

Roll-based thermoforming runs non-stop.

Perks: This speed allows labs to serve:

Thousands of aligners per shift

Continuous batches

Predictable daily output

No loading. No unloading. No waiting.

Large DSOs

Multi-clinic chains

International aligner brands

You stop worrying about bottlenecks.

2. Zero Sheet Wastage

Traditional sheets waste material at:

- Edge trimming

- Frame cutting

- Alignment errors

Roll-based systems optimise every millimetre of material. This reduces:

- Scrap

- Rejection rates

- Cost per aligner

- Over a year, these savings become massive.

3. Consistent Force Delivery

Force delivery depends on:

- Uniform thickness

- Controlled heating

- Even stretching

Roll-based systems maintain stable thermal zones across the entire forming area.

This creates:

- Identical aligners

- Predictable movement

- Fewer refinements

- Better clinical outcomes

- Consistency becomes built into the process.

4. Automation Reduces Human Error

Manual loading creates variation. Different operators produce different results. Fatigue causes mistakes. Training takes time.

Roll-based systems:

- Run automatically

- Maintain identical forming cycles

- Reduce operator dependency

- Improve quality control

- Your production becomes a system, not a skill.

5. Lower Cost Per Aligner at Scale

At small volumes, single sheet thermoforming works fine, but at large volumes, it becomes expensive and complex.

Roll-based thermoforming reduces:

- Labor cost

- Material waste

- Rework

- Downtime

- Cost per aligner drops as volumes rise. That is how large aligner brands stay profitable.

Who Needs Roll-Based Thermoforming?

Roll-based systems make sense for:

- Growing aligner labs

- In-house DSO production units

- High-volume export labs

- Aligner brands building private labels

- If your monthly production crosses a few thousand aligners, sheet forming will start limiting your growth.

The Industry Direction Is Clear. Global aligner leaders already run automated production lines. Manual sheet forming will not support the next decade of growth.

The future belongs to:

- Automation

- Standardization

- Industrial-grade manufacturing

- Roll-based thermoforming fits perfectly into this future.

Labs that invest early gain:

- Higher output

- Better margins

- Stronger quality control

- Global scalability

This is not just a technology upgrade. It is a business upgrade.

Final Thought

Aligner production is no longer a craft. It is a manufacturing business. The labs that win will think like manufacturers, not workshops. That means better materials, smarter machines and scalable systems.

Taglus supports next-generation aligner production with high-performance roll and sheet materials engineered for automated thermoforming environments. The goal stays simple. Help labs build faster, stronger, and more profitable aligner systems.

Know More About Us

SignUp To Our Newsletter And Get To Know More About Taglus

Copyrights@taglus-2026

*Taglus is a trademark of Vedia Solutions

Leave a Reply