Enquire Form

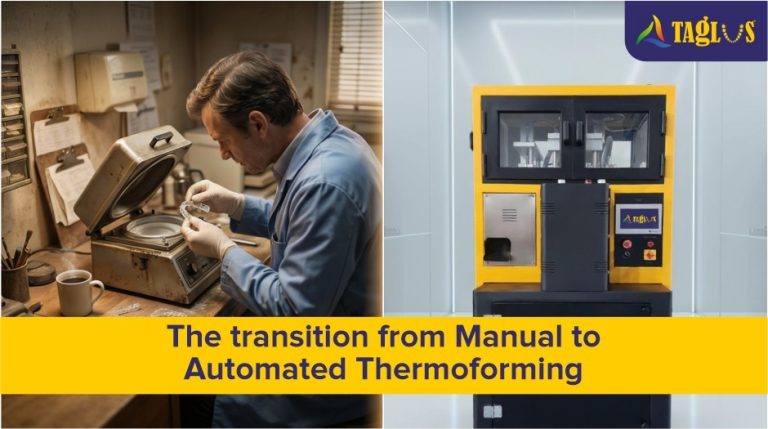

Making the Leap: When and How to Transition from Manual to Automated Thermoforming

Manual aligner production provided a simple and accessible way to produce aligners. But now that your aligner production needs are growing, you need something more efficient which can produce aligners at a faster rate without compromising the quality of aligners. Ultimately, switching to automated thermoforming is the need of the hour for you. But it’s not a small decision. You have to consider the cost, the disruption to your current workflow, training of your staff and more. But, at some point, sticking with manual processes would start costing you more than the cost of transition. This guide will help you in finding the most effective ways and some tricks which will help you in smoothly transitioning to the automated aligner workflow, saving you a lot of trial and error in this exciting journey.

The Benefits of Automated Thermoforming Workflows:

1 – Volume – If your team is producing hundreds of aligners everyday then it is time for you to move towards automation. Automated workflows allow a continuous production of aligners without much intervention from your team, saving you hours of manual labour while fulfilling your needs efficiently. It allows you to have shorter TATs and accommodate sudden high demands efficiently.

2 – Consistency – Manual processes can always lead to variations. Maintaining consistency in terms of quality becomes difficult, especially when the production volume is increasing. This can be avoided using automated thermoforming workflows.

3 – Efficiency – Automated processes are definitely faster as compared to manual thermoforming workflows. This enhances your efficiency when you are dealing with volume production.

4 – Cost – Growing using an automated thermoforming workflow becomes easier. Trying to accommodate growing requirements in the manual workflow would require hiring more people to handle the increased volume. And the ongoing costs add up faster than you might expect. Investing in automation is a far more sensible decision than expanding the team indefinitely.

Step-Wise Transition to Automated Thermoforming Workflows:

1 – Assessment:

Analyse the ongoing situation of your thermoforming workflow. What’s the current volume of production? Which tasks are eating up the most time? You need to know where you are before you can plan your automation.

It is a good idea to talk to your team who work around the clock to fulfil your thermoforming requirements. Your operators will have opinions about what’s working and what’s consuming a lot of time, hampering their efficiency. Additionally, getting them involved early would make them feel more involved and a part of this transition rather than just being a passive change.

2 – Planning & Preparation:

This phase is busier than it looks on paper. This is the practical stuff that you need to sort before you can actually start implementing your plan. You need to check and locate spots where the machines are going to be physically kept. Get the necessary electrical work done.

These details matter more than you would think.

Focus on planning training for your staff. If only a limited staff is trained, what happens if they are sick or on holiday? Does someone else know how to run it? If you are operating round the clock, how does knowledge get shared across different shifts? You need to find answers for all of these questions.

3 – Implementation:

The actual installation usually goes fairly smoothly. Don’t switch over completely straightaway. Keep your manual setup running for a bit while you build confidence with the automated system. It feels safer, doesn’t it? And it is. You’re not gambling your entire operation on equipment you’ve been using for all of five minutes. Gradually shift more work across as everyone gets comfortable.

Taglus Autoform Roll Machine: Your Ultimate Bet for High-Volume Production

Taglus Autoform Roll Machine is the ultimate option while transitioning from manual to automated thermoforming workflow. It is one of the world’s smallest automated thermoforming roll machines, which matters when space is at a premium. It can produce 120 aligners per hour, which is rather impressive for something that won’t dominate your entire workspace. It handles everything from the infeed carousel for your 3D models right through to the ejection station, with automatic film placement and forming in between. That seamless integration means fewer opportunities for things to go wrong and less manual handling throughout the process. This is exactly what you are looking for when moving to automation. At roughly 300kg and running on standard 220V single-phase power, it doesn’t require the kind of facility modifications that some larger industrial equipment demands.

Conclusion:

Transitioning from manual to automated thermoforming can be performed smoothly with proper planning and careful execution. You need to involve your teams early and maintain realistic expectations about the time it will take for your team to adapt to it.

Exploring automation isn’t just about efficiency; it’s about positioning your operation to meet future demands without compromising quality or exhausting your team. And that’s a decision that tends to justify itself fairly quickly once the transition is complete.

The Taglus Autoform Roll machine offers a practical entry point into automation. It’s designed with growing laboratories in mind, balancing capability with accessibility in a way that makes the transition more manageable than many anticipate. To know more about the Taglus Autoform Roll machine, contact us now.

Know More About Us

SignUp To Our Newsletter And Get To Know More About Taglus

Copyrights@taglus-2026

*Taglus is a trademark of Vedia Solutions

Leave a Reply