Enquire Form

Pressure vs Vacuum Forming: Which Method Delivers Better Aligners?

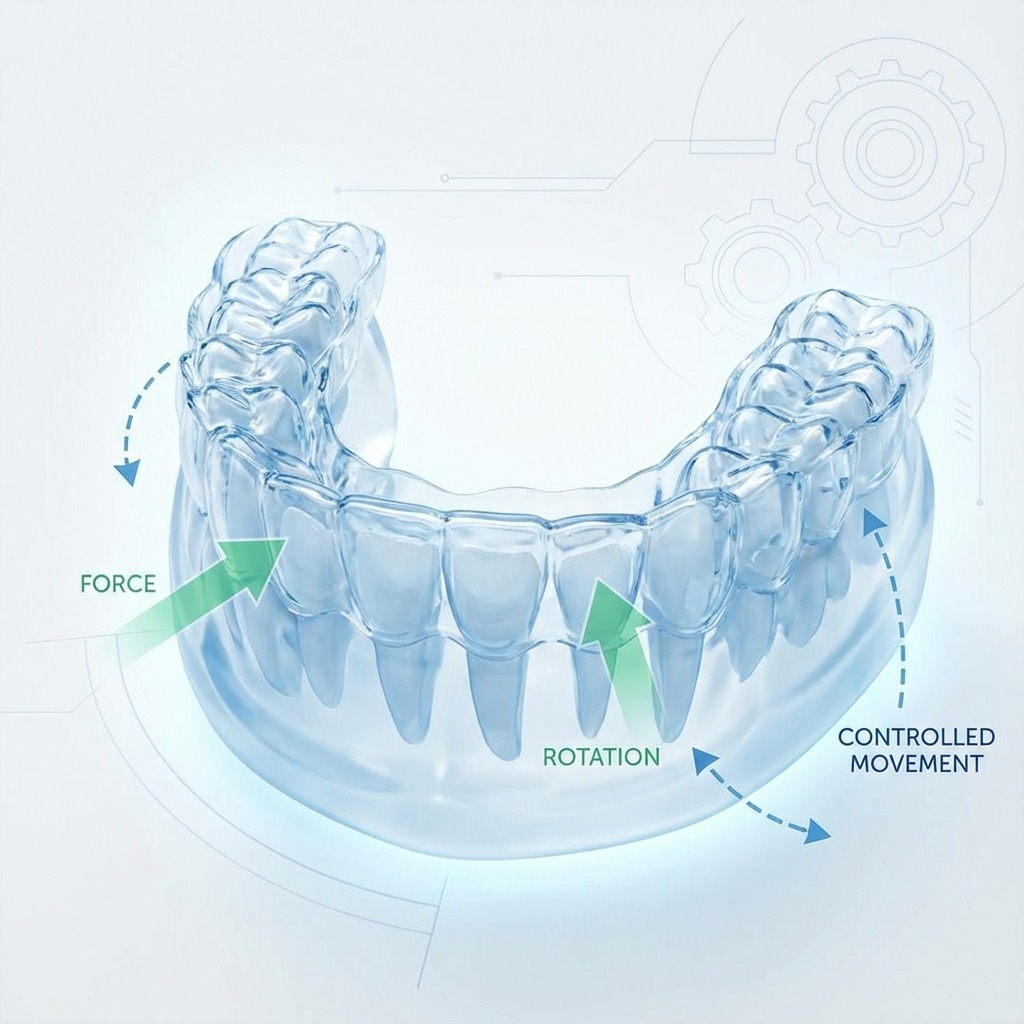

Aligners bring in tooth movement by exerting forces on teeth. It directly depends on how well the aligner is manufactured, and thermoforming is a commonly employed method to manufacture aligners. Aligners which are not thermoformed properly yield ineffective results or may at times generate excessive forces or incorrectly directed forces on the tooth, which can lead to unnecessary tooth movements. Thus, the quality of thermoforming impacts the result of the alignment treatment as well as the experience of the patient. There are two primary methods of aligner thermoforming: pressure forming and vacuum forming. These two methods differ in their specific qualities. One should opt for the method that best suits their requirements. Let’s learn more about vacuum forming and pressure forming to understand which is the better option when it comes to manufacturing aligners.

PRESSURE FORMING vs VACUUM FORMING:

What is Pressure Forming?

In pressure forming, positive air pressure is applied in addition to a vacuum to force the heated sheet onto a dental model.

What is Vacuum Forming?

In vacuum forming, negative air pressure is used to create suction which pulls the heated sheet towards the dental model.

Difference Between Pressure vs Vacuum Forming:

The two methods differ in quite a few ways that can impact the output of the aligner thermoforming workflow. Let’s explore how they differ:

| Quality | Pressure Forming | Vacuum Forming |

|---|---|---|

| Detail and Edges | Sharp detail, crisp edges, good for complex shapes | Simpler shapes, less detail, edges can be rounded |

| Surface Finish | Smooth, high-quality, glossy finish | Basic finish, less glossy, may show imperfections |

| Thickness Control | Works well with thick and thin sheets, very precise | Handles thick sheets but has less accuracy |

| Production Speed | Slightly slower due to extra pressure steps | Faster and efficient for bulk production |

| Tooling Cost | Higher, needs stronger moulds | Lower, simple moulds work |

| Design Flexibility | Best for aligners needing fine details or unique textures | Good for simpler appliances |

| Strength and Fit | Enhanced, closely fits the mould for better adaptation | Good, fit is accurate, but not as tight |

The Better Method for Aligner Thermoforming:

Looking at both options side by side, pressure forming does seem to have the edge when you want to produce top-quality aligners. Pressure forming machines require a bit more investment upfront and perhaps take slightly longer per cycle, but the benefits you are getting in return might just be worth it.

Precision manufacturing is the most important thing in alignment treatment. Pressure forming creates a tight adaptation to the dental model, capturing every little detail of the tooth anatomy. The crisp edges and contours translate directly into how well the aligner grips the teeth and deliver the intended forces. When patients wear something that fits properly from day one, they are probably going to be more compliant with the treatment plan.

The glossy, smooth finish isn’t just about aesthetics either. Patients notice the difference when they run their tongue over the aligner. A rougher surface can feel uncomfortable and might even put people off wearing them as much as they should. Plus, that smooth finish makes the aligners easier to clean, which matters for oral hygiene throughout the treatment period.

There is also something to be said about consistency across your production. When you are manufacturing multiple aligners for different stages of treatment, having predictable thickness control means each one should perform as expected. You are less likely to encounter situations where an aligner cracks unexpectedly or doesn’t apply force quite right because the material thinned out too much in certain areas.

Some dental professionals might hesitate because of the higher tooling costs, but the reduction in remakes and adjustments actually saves time and money in the long run.

Vacuum forming certainly has its place. For manufacturing simpler appliances, it certainly gets the job done. But when you are looking at complex tooth movements, patients with sensitive gums, or cases where you simply can’t afford a poor fit, pressure forming appears to be the more reliable choice. The enhanced strength and superior adaptation give you better control over the treatment outcome.

TAGLUS: YOUR EFFICIENT ALIGNER THERMOFORMING PARTNER:

Taglus offers reliable solutions designed specifically for aligner production. The exclusive range of thermoforming equipment includes Taglus Autoform, which can produce around 120-140 aligners per hour and can turn out to be handy for busy practices. The Taglus Duoform is more compact while still delivering consistent 4 bar pressure for precise adaptation. For larger operations, there’s the Taglus Autoform Roll Machine, which uses roll material instead of individual sheets for continuous high-volume production. All three machines are engineered to deliver the benefits of pressure forming while keeping your workflow efficient.

Conclusion:

The thermoforming method you choose today shapes the quality of treatment outcome you yield tomorrow. Pressure forming might require a bit more upfront commitment, but the payoff shows in ways that matter: aligners that fit better, patients who feel more comfortable, and treatment plans that work as intended. If you would like to know more about our machines and how they might fit into your workflow, feel free to reach out to us. We are here to help you find the solution that works best for your thermoforming workflow.

Know More About Us

SignUp To Our Newsletter And Get To Know More About Taglus

Copyrights@taglus-2026

*Taglus is a trademark of Vedia Solutions

Leave a Reply