Enquire Form

From Scan to Smile: How Digital Dentistry is Shortening Aligner Delivery Times.

Have you ever wondered why patients today expect their aligners in days rather than weeks? The answer lies in how fast dentistry is evolving.

A few years back, it was a very normal and routine task for the dentist to wait weeks for dental solutions. Whether it be for aligners or other prostheses, coordinate with the lab with each step.

Impressions had to be taken manually, packed, shipped, and then re-checked once the models reached the lab. If anything went wrong, it was back to square one. That meant patients often waited three or four weeks to get their first tray.

Dentistry then had not so evolved that a dentist could have imagined the workflow any other way round.

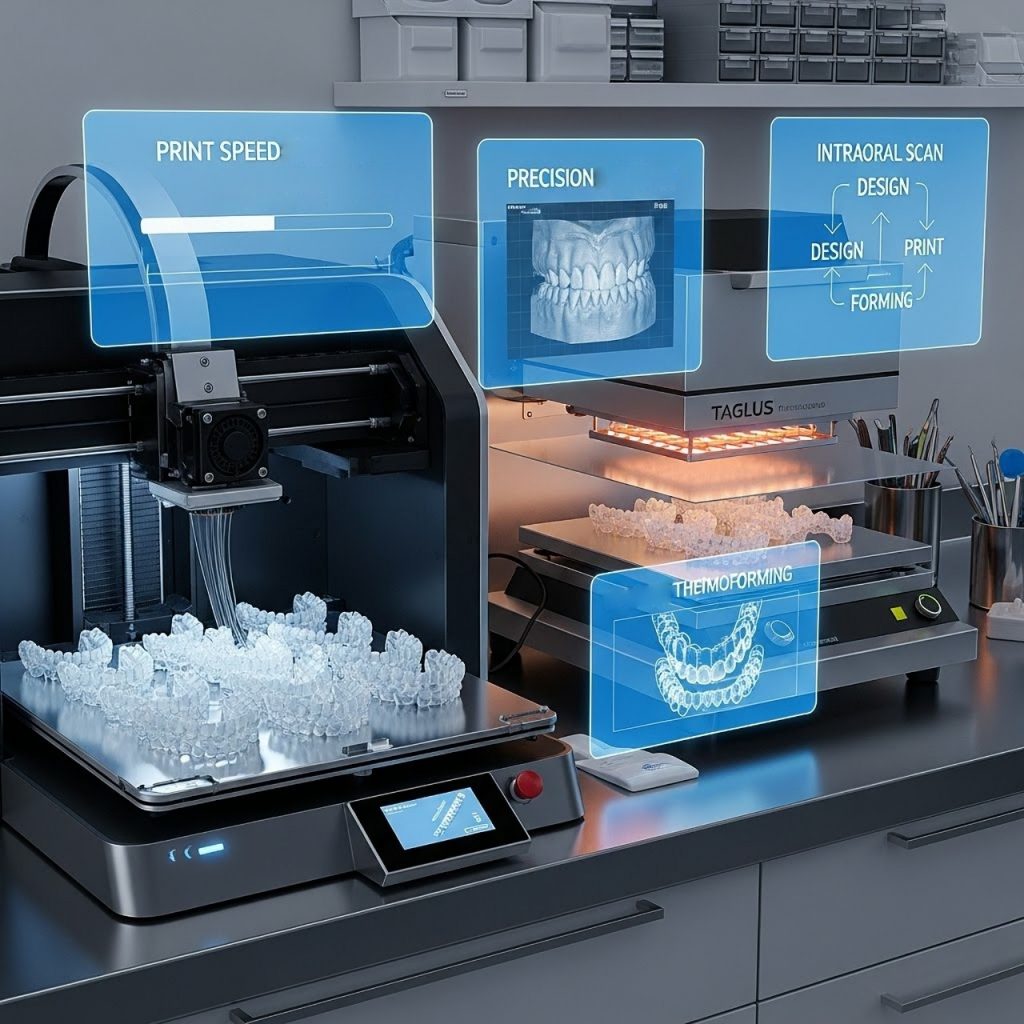

Today, with intraoral scanners, 3D printers, and materials like Taglus thermoforming aligners and retainer sheets, the process feels almost futuristic and digital.

A digital scan is uploaded in minutes; there are no manual impressions to be rectified again and again, treatment is planned digitally, and labs can start forming aligners without the frustrating delays of the past.

Patients notice the difference right away with perks like fewer appointments, less waiting, better results, and a lot more confidence in starting the aligner treatment.

In this article, we will dive into the advancements that have caused the aligner treatment time to be this short.

Why the Old Way Took Too Long

Before jumping into the present and future, let’s understand what it took to travel from the conventional ways to the modern era of dentistry.

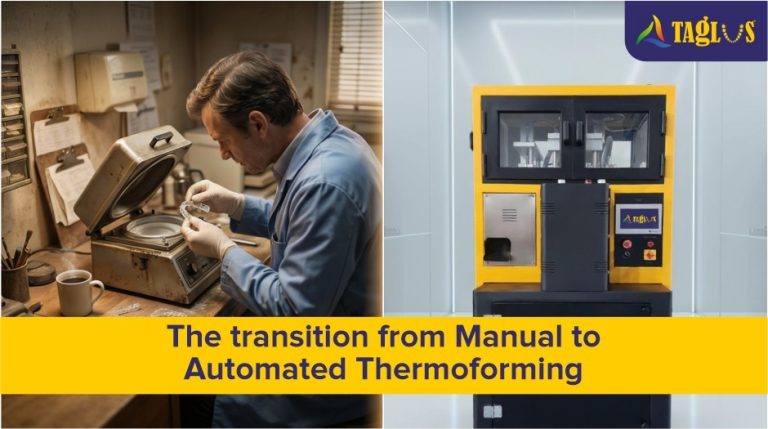

Earlier, aligner delivery was a drawn-out process. Dentists took physical impressions, shipped them to labs, waited for stone models, wax-ups, and multiple manual steps before aligners were fabricated. There were fewer potential machines and materials to fabricate aligners of the desired quality and quantity.

Other than this, dentists were depending on the labs to fabricate the aligners, which only added to the delay.

For the same reasons, Impression errors meant costly retakes, increased appointments and asking about the whereabouts of the lab.

The result? Tired dental professionals and delayed treatments.

The Digital Shift: Faster, Cleaner, Smarter

Enter intraoral scanning and CAD/CAM technology. Now, instead of impressions, dentists capture a 3D oral scan, which, if taken correctly, takes almost 30 seconds.

That digital file reaches the lab instantly, where treatment planning begins digitally, and models are 3D-printed for forming aligners.

The aligner material is certified and approved, which gives predictable results with no reworks. So basically, what once took weeks now takes less than a week — in some cases, just a few days.

The workflow accelerated because there are,

- No messy impression errors and reworks

- No shipping delays or discrepancies

- Streamlined digital planning with almost zero miscalculation that leads to desired outcomes

- Direct-to-print models with minimal to no human interference

A process that was once slow and fragile is now fast, precise, and reliable. This has become a reality in dentistry because of the futuristic advanced technologies, upgraded materials that go along with the cutting-edge process, and the advanced tools and machines that accelerate the whole process.

Where AI and Automation Step In

Artificial intelligence and automation have added another layer of efficiency in delivering aligners. Around the globe, these platforms are being used to sharpen the aligners workflow process in the most beneficial ways, both to the dentist and patients.

- AI-driven treatment planning

Artificial intelligence is being utilised widely to analyse scans and predict tooth movement faster than ever. The studies have claimed that tooth segmentation accuracy has increased to 98%. This not only helps in transforming the labour-intensive process and mathematical algorithm into rapid data-driven algorithms and quick decision-making.

- Automated design systems

Automated designing systems streamline the aligner workflows by reducing manual steps, ensuring consistency and precision. They also help in minimizing human errors and some biased protocols that, when used manually, are not subjected to personalized case treatment design.

- Cloud-based platforms

These platforms allow instant collaboration between clinics and labs, cutting down communication delays.

They also allow for instant updates, with these advancements, what once required back-and-forth discussions can now be finalized in hours.

Why Speed Matters

Quick delivery isn’t just convenient, it drives compliance. When patients receive aligners fast, they stay motivated and committed. For clinics, shorter timelines mean fewer dropouts, smoother patient flow, and more cases each month.

Looking Ahead

Digital dentistry is only getting faster. AI planning, chairside 3D printing, and smarter manufacturing are already here. Same-day aligners may soon be standard.

But even today, shifting from impressions to digital scans is a revolution in itself. Patients no longer think “long wait.” They think “modern, fast, and accurate.”

In a nutshell

Aligner treatment isn’t just about moving teeth, it’s about patient experience. With digital workflows and advanced material like Taglus thermoforming sheets, clinics and labs can deliver speed, precision, and trust.

Taglus sheets are engineered for consistency and performance, ensuring every aligner formed is crystal-clear, durable, and patient-comfort friendly. By combining cutting-edge digital workflows with the reliability of Taglus, dentists and labs can confidently scale their aligner business- from scan to smile, faster than ever before.

Know More About Us

SignUp To Our Newsletter And Get To Know More About Taglus

Copyrights@taglus-2026

*Taglus is a trademark of Vedia Solutions

Leave a Reply